Summary

| Total savings : | ~ 640,000 t CO2 per year (PoA) and ~ 20,000 t CO2 per year (2 GS MSC projects) |

| Technology transfer : | Efficient wood gasi stoves that save 50% firewood and provide smoke-free cooking. Since this is a pyrolysis technology, charcoal is produced as a by-product. |

| Local environment : | Avoiding deforestation in the region and reducing indoor air pollution. |

| Further advantages : | Time and cost savings in firewood procurement; Fewer respiratory illnesses due to almost smoke-free cooking; Fast and flexible cooking on (wood) gas flame; Additional income from the sale of the charcoal produced during the cooking process. |

| Target group : | Households throughout India |

| Jobs : | Over 300 new jobs in production, sales and coal collection chain |

| Local partners : | Sapient Infotech (small company from Kolkata) |

Efficient wood gasification stoves as forest protection

In India, the forests have always been of great importance for the social, cultural and economic life of the people. Since time immemorial, people have used the forests as a source of firewood, fodder for animals, timber, etc. However, the rapid increase in population also increases the pressure on the forests. In some regions of India, up to 93% of the rural population, especially in poorer parts of the country, were still dependent on firewood for cooking in 2015 ¹.

The demand for firewood in India is higher than the supply of sustainable, renewable raw materials. This means that some of the wood used for cooking and the production of conventional charcoal comes from unsustainable sources. By introducing efficient stoves and replacing conventional coal, atmosfair reduces the need for wood in the long term and thus also the incentive for illegal logging and overexploitation of the forests. More wood remains in the forests, which counteracts the ongoing forest degradation in India ².

A special technology

Since 2012, atmosfair subsidizes the sale of highly efficient wood gas stoves that reduce firewood consumption by 50%.

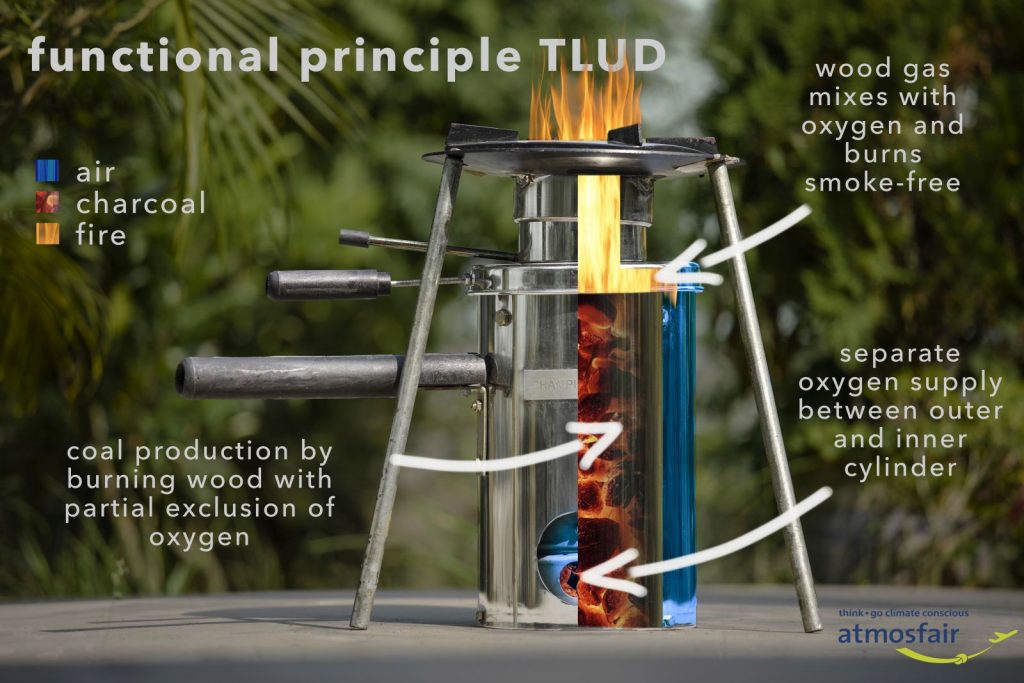

The wood gasification stove uses the TLUD (Top-Lit Up-Draft) technology. It involves igniting dry biomass fuel (wood or pellets) on top of a vertical container, starting a pyrolysis process. As a pyrolysis front moves down, the wood gas produced moves up and, as it exits the furnace, is mixed with oxygen from the air and burned in a flame suitable for cooking. The TLUD allows significant savings on firewood compared to traditional stoves and also produces charcoal.

Cooking like on gas and an additional income

Cooking on a wood gas flame is just as comfortable as cooking on a LPG stove, with no smoke and a very stable flame. The process of wood gasification also generates charcoal as a by-product which can be used by the households or sold. The projects offers to buy the charcoal back from households and then provides it to users of conventional charcoal like barbecue restaurants, which allows for additional CO2 savings.

Due to the reduced expenses for firewood and the revenues from charcoal sales, households can quickly recover the expenses for the stove. This improves the economic situation of locals and simultaneously prevents the destruction of the Bengal Tiger’s habitat.

Achieving climate targets in India

Status-Check: atmosfair is currently preparing an agreement with the host country to avoid double counting so that the project can be used in the future without restrictions to offset unavoidable residual emissions.

Share

Share Tweet

Tweet