Summary

| Total savings : | Approx. 32,900 tonnes of CO2 sink per year |

| Technology transfer : | Efficient wood gasification stoves that save around 50% firewood and enable smoke-free cooking. The by-product of cooking is biochar, which forms the basis of organic fertiliser and leads to increased crop yields, particularly in tropical, acidic soils. |

| Local environment : | Avoidance of deforestation in the region; Reduction of indoor air pollution; Regeneration of depleted soils; Improved water retention capacity of the soil |

| Further advantages : | Time and cost savings in the procurement of firewood; Fewer respiratory diseases thanks to almost smoke-free cooking; Additional income |

| Target group : | Families and farmers in rural India |

| Jobs : | ~170 new jobs in the coal collection chain, in the production of fertiliser and in agricultural consulting |

| Project partners : | Sapient Infotech (small company from Calcutta) and Somesh Dutta (specialist on sustainable farming) |

In India, atmosfair produces biochar on a decentralised basis in the villages to the east of Calcutta. We do not need expensive machinery for this. The biochar is produced as a by-product of cooking with the help of our efficient wood gasification stoves. Our field agents buy the biochar from the families every month and process it in our plant together with compost and dolomite to make a fertiliser. We sell this fertiliser to farmers in the region. Using the fertiliser creates a CO2 sink, while at the same time adding valuable nutrients to the soil.

The biochar project was created as a sub-project of our efficient cooking stoves in India. In April 2023, we carried out a pilot project with 4 villages. Due to the positive feedback and high demand, we set up a plant in Deganga to produce the biochar-based fertiliser in December 2023. Production has been running since January 2024. In the winter of 2024/2025, we built a second production facility for fertilizer in the Uluberia region and doubled the number of households in the project. We are currently working with approximately 60,000 stove users. This enables us to process 1800 tonnes of biochar into 3600 tonnes of fertiliser every month.

Our efficient wood gasification stoves

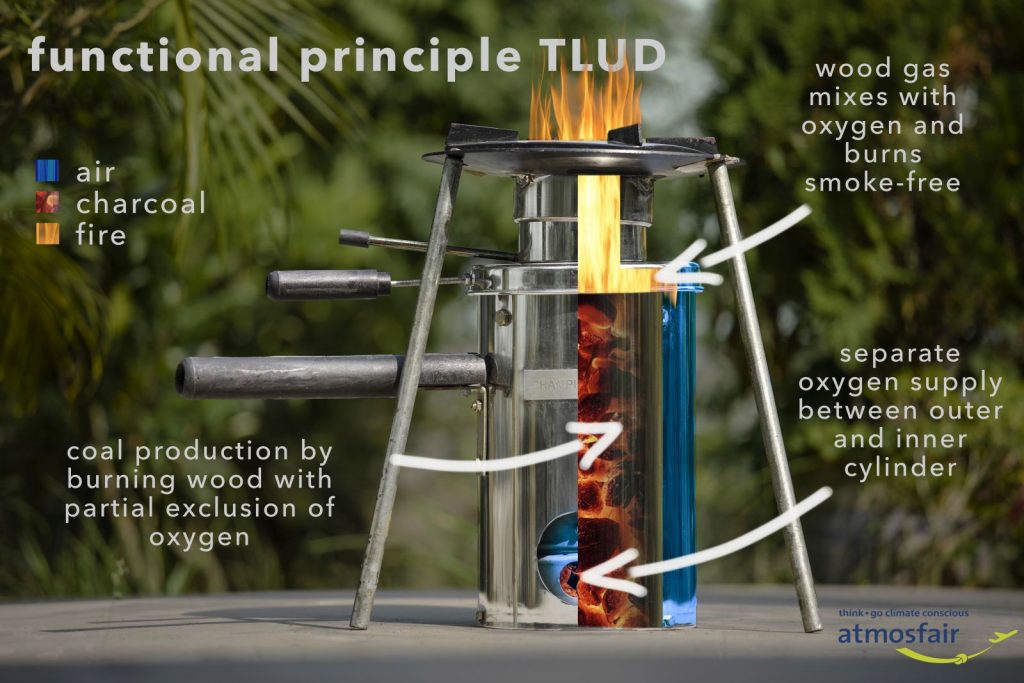

The stove technology in this project is a wood gasification stove that is sold to households that use firewood for cooking. In top-lit up-draft (TLUD) technology, dry biomass fuel (wood or pellets) is ignited on top of a vertical container, which starts the pyrolysis process. As a pyrolysis front moves downwards, the wood gas produced moves upwards and is mixed with oxygen from the air as it leaves the stove and burnt in a flame suitable for cooking.

Cooking on the wood gas flame created by the gasifier technology is just as convenient as cooking on an LPG cooker, with no smoke and a very stable flame. This reduces – especially for women and children – the serious health effects of indoor air pollution, which is the main cause of lung disease and eye irritation. In addition, the high efficiency of the stove means that around 50 % of firewood can be saved. The lifetime of the stove is about 7 years.

During cooking, the wood gasification process produces around 30 kg of biochar per month as a by-product. The project offers to buy the biochar from the stove users. By selling the biochar, the households have a regular and secure additional income of almost one month’s salary per year at the local rate of pay. Once a month, the biochar produced is collected from the families by our field agents. The quality of the biochar is also checked during this process. The biochar is then crushed in our plant and mixed with compost and dolomite to make a fertiliser that is sold to farmers in the region. This replaces chemical fertilisers.

The families who use our efficient gasifier stoves live in small villages on the outskirts of Kolkata.

Biochar - a multi talent

Plants absorb CO2 from the air using solar energy and incorporate the carbon into their cell structures. They thus naturally remove CO2 from the atmosphere. Humans can process the biomass of the plants into biochar before decomposition sets in and the CO2 is released again. In the form of biochar, the carbon remains stored in the soil for centuries. Even if the biochar is simply applied to the top layers of soil or ploughed under. Biochar resists the biological decomposition processes in the soil due to its special structure. To ensure this, the ratio between hydrogen and organic carbon, of which the biochar is composed, must be below a certain value (Persistence of biochar in soil). This value can be clearly tested in the laboratory. If this value is reached, science says that after 1000 years at least 75 % of the carbon is still safely bound in the soil. When calculating negative emissions, we subtract all other project emissions from this proportion.

Biochar has many other positive effects. Similar to a sheet of A4 paper, which can be compressed into a small ball by folding, tearing and pressing it, biochar offers a lot of porous surface area for binding nutrients in a very small space. When mixed with compost, it leads to increased crop yields, especially in tropical soils. In addition, biochar stores water from heavy rainfall events during the monsoon season and releases it back to the plants over a period of weeks. As a water reservoir, it prevents nutrients from being washed out of the soil. Other important factors also come into play: the basic cycles of the ecosystem are maintained. The biochar is returned to the soil exactly where the plants grew. Important minerals and trace elements remain in the soil and the soil does not leach out.

Biochar thus combines carbon storage with sustainable agriculture.

The region

The fields in the project region are small. Farmers in West Bengal own an average of 0.77 hectares of land, which they cultivate mainly by hand. Most of them are organized in so-called “farmer clubs”. In these farmers’ clubs, they buy fertilizers and sell their harvests collectively. Tractors are also hired jointly to cultivate the fields three times a year. The use of chemical fertilizers has accelerated soil degradation in India. Yields are declining and farmers are looking for alternative fertilizers. The carbon content of soils is depleted due to intensive inorganic agricultural practices. Biomass must be returned to the soil to restore its health. atmosfair helps farmers to make this a reality.

The map below shows the geographical location of the TLUD stoves from the project and the site of our production facility where the fertilizer is manufactured.

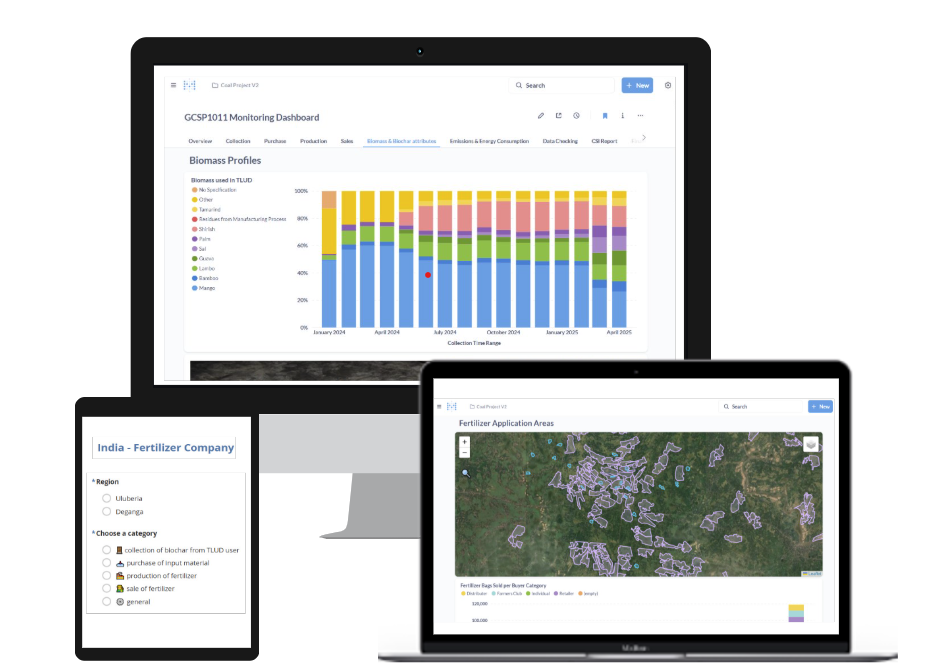

Digital Real-Time Monitoring

In this project, we rely on digital real-time monitoring to ensure transparent and efficient tracking of the entire biochar value chain from production onward. Every step is digitally recorded — from the collection of biochar, through its processing and blending into an organic fertilizer, to the sale and application of the fertilizer, including GPS coordinates of the deployment locations. These continuously available data allow us to precisely track quantities and trends. For example, we can verify each month whether biochar was collected from all 60,000 households, whether the mixing ratios of the fertilizer’s ingredients are correct, and how much biochar and finished fertilizer we currently have in storage.

The monitoring tool we developed specifically for our project has been officially recognized by Carbon Standards International.

Carbon Standards International (CSI)

There is currently no authorised methodologies under the Clean Development Mechanism (CDM) and the Gold Standard for calculating carbon sinks through biochar produced in efficient cookstoves. For certification, atmosfair has chosen the Carbon Standard International (CSI), which focusses on the production and incorporation of biochar. Compared to other standards, the calculation of carbon sinks can be considered rather conservative.

Share

Share Tweet

Tweet